What is a Stepper Motor?

Stepper motors are DC motors that move in discrete steps. They have multiple coils that are organized in groups called "phases". By energizing each phase in sequence, the motor will rotate, one step at a time.

With a computer controlled stepping you can achieve very precise positioning and/or speed control. For this reason, stepper motors are the motor of choice for many precision motion control applications.

Stepper motors come in many different sizes and styles and electrical characteristics. This guide details what you need to know to pick the right motor for the job.

With a computer controlled stepping you can achieve very precise positioning and/or speed control. For this reason, stepper motors are the motor of choice for many precision motion control applications.

Stepper motors come in many different sizes and styles and electrical characteristics. This guide details what you need to know to pick the right motor for the job.

What are stepper motors good for?

- Positioning – Since steppers move in precise repeatable steps, they excel in applications requiring precise positioning such as 3D printers, CNC, Camera platforms and X,Y Plotters. Some disk drives also use stepper motors to position the read/write head.

- Speed Control – Precise increments of movement also allow for excellent control of rotational speed for process automation and robotics.

- Low Speed Torque - Normal DC motors don't have very much torque at low speeds. A Stepper motor has maximum torque at low speeds, so they are a good choice for applications requiring low speed with high precision.

What are their limitations?

- Low Efficiency – Unlike DC motors, stepper motor current consumption is independent of load. They draw the most current when they are doing no work at all. Because of this, they tend to run hot.

- Limited High Speed Torque - In general, stepper motors have less torque at high speeds than at low speeds. Some steppers are optimized for better high-speed performance, but they need to be paired with an appropriate driver to achieve that performance.

- No Feedback – Unlike servo motors, most steppers do not have integral feedback for position. Although great precision can be achieved running ‘open loop’. Limit switches or ‘home’ detectors are typically required for safety and/or to establish a reference position.

Types of Steppers

There are a wide variety of stepper types, some of which require very specialized drivers. For our purposes, we will focus on stepper motors that can be driven with commonly available drivers. These are: Permanent Magnet or Hybrid steppers, either 2-phase bipolar, or 4-phase unipolar.

Motor Size

One of the first things to consider is the work that the motor has to do. As you might expect, larger motors are capable of delivering more power. Stepper motors come in sizes ranging from smaller than a peanut to big NEMA 57 monsters.Most motors have torque ratings. This is what you need to look at to decide if the motor has the strength to do what you want.

NEMA 17 is a common size used in 3D printers and smaller CNC mills. Smaller motors find applications in many robotic and animatronic applications. The larger NEMA frames are common in CNC machines and industrial applications.

The NEMA numbers define standard faceplate dimensions for mounting the motor. They do not define the other characteristics of a motor. Two different NEMA 17 motors may have entirely different electrical or mechanical specifications and are not necessarily interchangeable.

Step Count

The next thing to consider is the positioning resolution you require. The number of steps per revolution ranges from 4 to 400. Commonly available step counts are 24, 48 and 200.Resolution is often expressed as degrees per step. A 1.8° motor is the same as a 200 step/revolution motor.

The trade-off for high resolution is speed and torque. High step count motors top-out at lower RPMs than similar size. And the higher step-rates needed to turn these motors results in lower torque than a similar size low-step-count motor at similar speeds.

Gearing

Another way to achieve high positioning resolution is with gearing. A 32:1 gear-train applied to the output of an 8-steps/revolution motor will result in a 512 step motor.A gear train will also increase the torque of the motor. Some tiny geared steppers are capable of impressive torque. But the tradeoff of course is speed. Geared stepper motors are generally limited to low RPM applications.

Shaft Style

Another thing to consider is how the motor will interface with the rest of the drive system. Motors are available with a number of shaft styles:- Round or "D" Shaft: These are available in a variety of standard diameters and there are many pulleys, gears and shaft couplers designed to fit. "D" shafts have one flattened side to help prevent slippage. These are desirable when high torques are involved.

- Geared shaft: Some shafts have gear teeth milled right into them. These are typically designed to mate with modular gear trains.

- Lead-Screw Shaft: Motors with lead-screw shafts are used to build linear actuators. Miniature versions of these can be found as head positioners in many disk drives.

Wiring

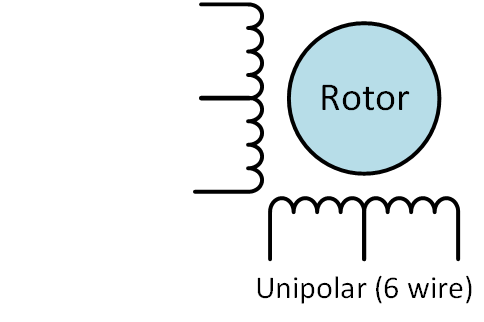

There are many variations in stepper motor wiring. For our purposes, we will focus on steppers that can be driven with commonly available drivers. These are Permanent Magnet or Hybrid steppers wired as 2-phase bipolar, or 4-phase unipolar.Coils and Phases

A stepper motor may have any number of coils. But these are connected in groups called "phases". All the coils in a phase are energized together.Unipolar vs. Bipolar

Unipolar drivers, always energize the phases in the same way. One lead, the "common" lead, will always be negative. The other lead will always be positive. Unipolar drivers can be implemented with simple transistor circuitry. The disadvantage is that there is less available torque because only half of the coils can be energized at a time.Bipolar drivers use H-bridge circuitry to actually reverse the current flow through the phases. By energizing the phases with alternating the polarity, all the coils can be put to work turning the motor.

A two phase bipolar motor has 2 groups of coils. A 4 phase unipolar motor has 4. A 2-phase bipolar motor will have 4 wires - 2 for each phase. Some motors come with flexible wiring that allows you to run the motor as either bipolar or unipolar.

No comments:

Post a Comment